Our PET bottle washer system is designed to revolutionize your recycling process with unmatched efficiency and reliability. Using the latest cleaning technology, contaminants, labels and other foreign matter are thoroughly removed from PET bottles, ensuring an exceptionally high quality final product. In addition to its impressive performance, the system has been designed with energy savings in mind to reduce operating costs while ensuring the highest efficiency. Its eco-friendly design minimizes water consumption and uses biodegradable cleaning agents, making it the ideal choice for companies committed to sustainability and reducing their environmental footprint. Choose our system to optimize your recycling processes and contribute to a cleaner, greener future.

functional principle

Learn how our recycling production line efficiently processes PET bottles.

Efficient shredding mechanism

The PET bottle recycling machine quickly crushes bottles into small pieces, increases recycling efficiency and prepares the materials for further processing.

Advanced sorting technology

Equipped with the latest sorting technology, it precisely separates plastics and contaminants, ensuring high-quality and pure recycled materials.

User-friendly interface

The intuitive user interface allows users to easily monitor, adjust settings, track performance, and troubleshoot issues effortlessly.

Compact design

The compact design fits into small facilities and urban spaces, saves space and enables easy installation and operation without requiring much space.

durability and low maintenance

Made from robust materials, it can withstand continuous use, requires minimal maintenance and minimizes downtime and operating costs.

energy efficiency

Thanks to energy-efficient technology, it reduces electricity consumption, lowers costs and supports sustainable recycling practices.

de-baling machine

The first step in our plastic bottle washing line is to break up the compacted bales of PET bottles into a free-flowing stream. Once the bales are "broken down", the bottles can be freely passed on to the next machine.

drum

The trommel is an optional device, a slowly rotating tunnel with small holes slightly smaller than the PET bottles. Small contaminants such as glass, metals, stones/dirt, paper, etc. can fall through the holes while the PET bottles are passed on to the next machine.

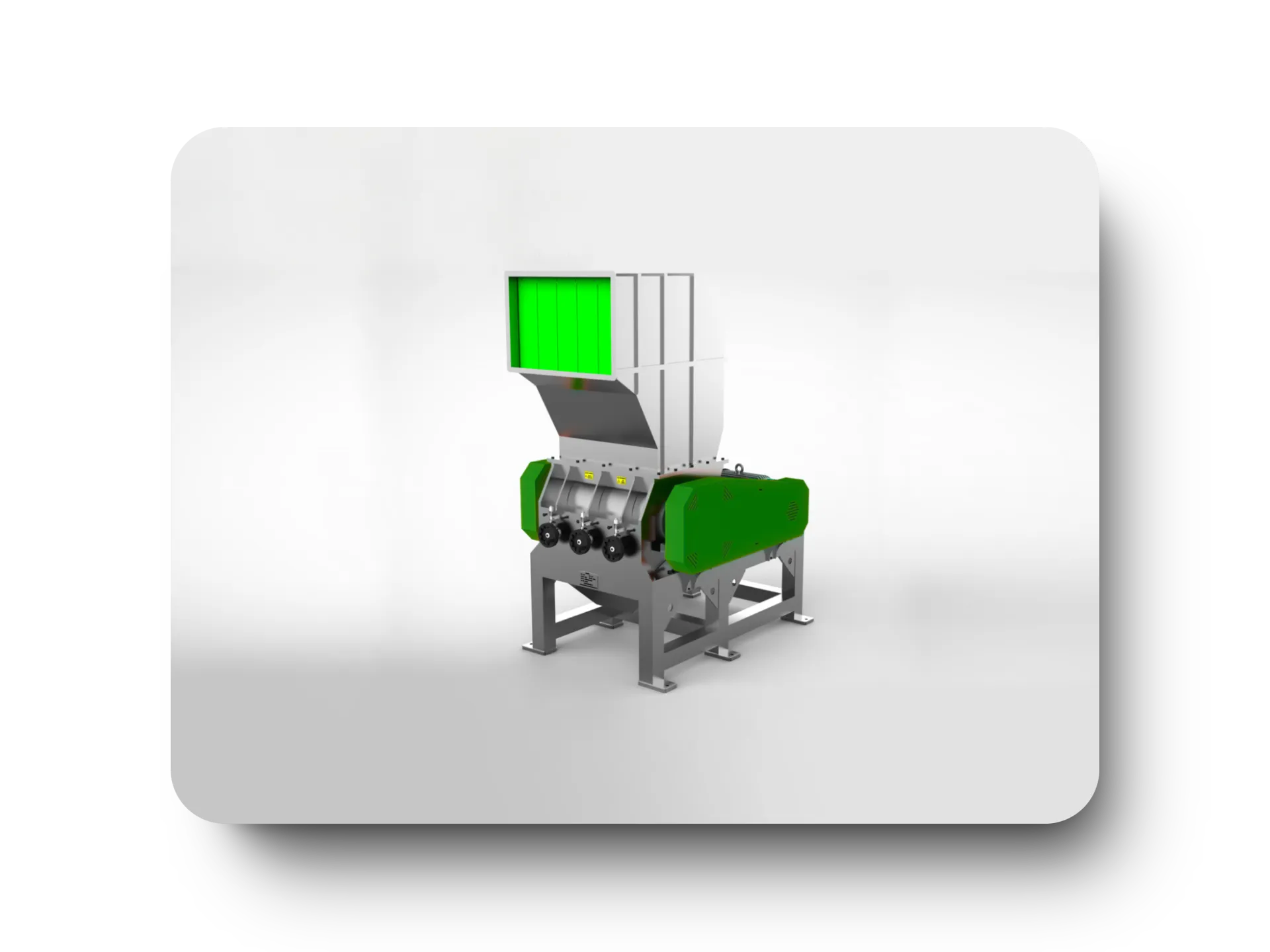

wet plastic shredder/granulator

Sometimes referred to as a plastic shredder, our plastic granulator machine cuts the PET bottles into small flakes measuring 10-15mm. During the cutting process, water is continuously sprayed into the cutting chamber, allowing this wet granulation process to pre-treat and partially clean the material before it is passed on to the next machine.

air separator

Air classification is a method of separating lighter materials from heavier ones. The main purpose of using an air separator is to remove contaminants such as paper, cardboard and plastic labels from the PET flakes.

sink/float separation basin

Using water as a medium, floating materials are separated from sinking materials. When recycling plastic bottles, PET plastic sinks, while plastic film (bottle labels) and PP/PE plastic (bottle caps) float on the surface. A screw conveyor at the bottom of the sink/float separation tank transports the PET plastic to the next machine.

hot wash system

Hot-washed PET flakes have a higher value because this process dissolves adhesives (used to attach labels to the bottles) as well as remaining beverage and food residues that are difficult to remove in a cold-wash process. Although only water can be used in the hot-wash system, detergents can be added for better results.

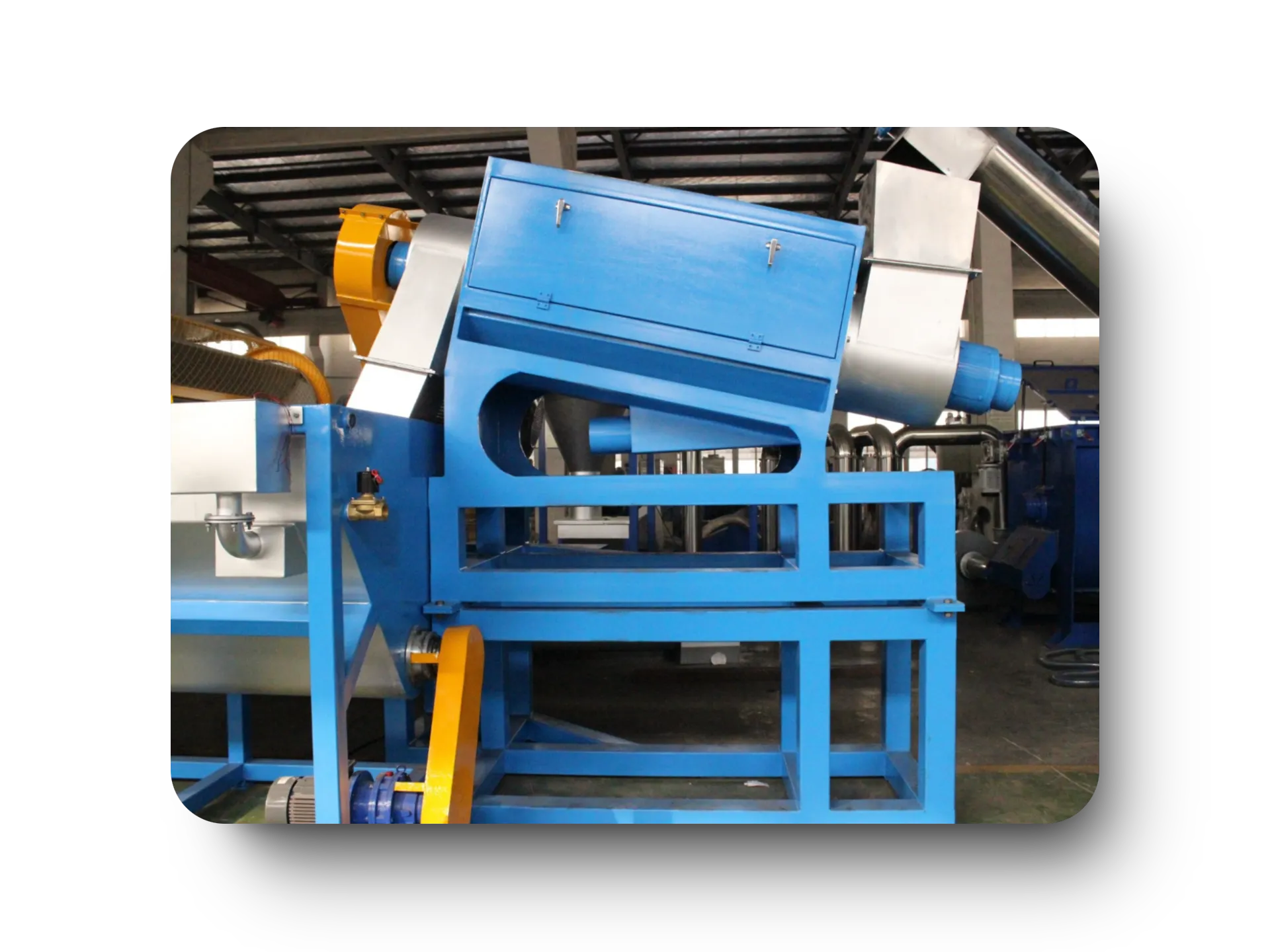

friction washer

An efficient cold water cleaning device, the high-speed friction washer, uses friction as a mechanical method to remove difficult-to-remove dirt and deposits from the PET flakes.

dewatering machine

The first step in the drying process: Our centrifugal dewatering machine uses centrifugal force to remove much of the water from the PET flakes before they are passed on to our thermal dryers.

thermal dryer

The PET flakes are sucked from the dewatering machine into the thermal dryer, where they are transported through a series of stainless steel pipes and mixed with hot air. This process removes the remaining moisture through dehydration. A connected cyclone separator mixes the PET flakes with cool air and prepares them for storage in the product silo.

product silo

A storage tank for the clean, dry PET flakes.

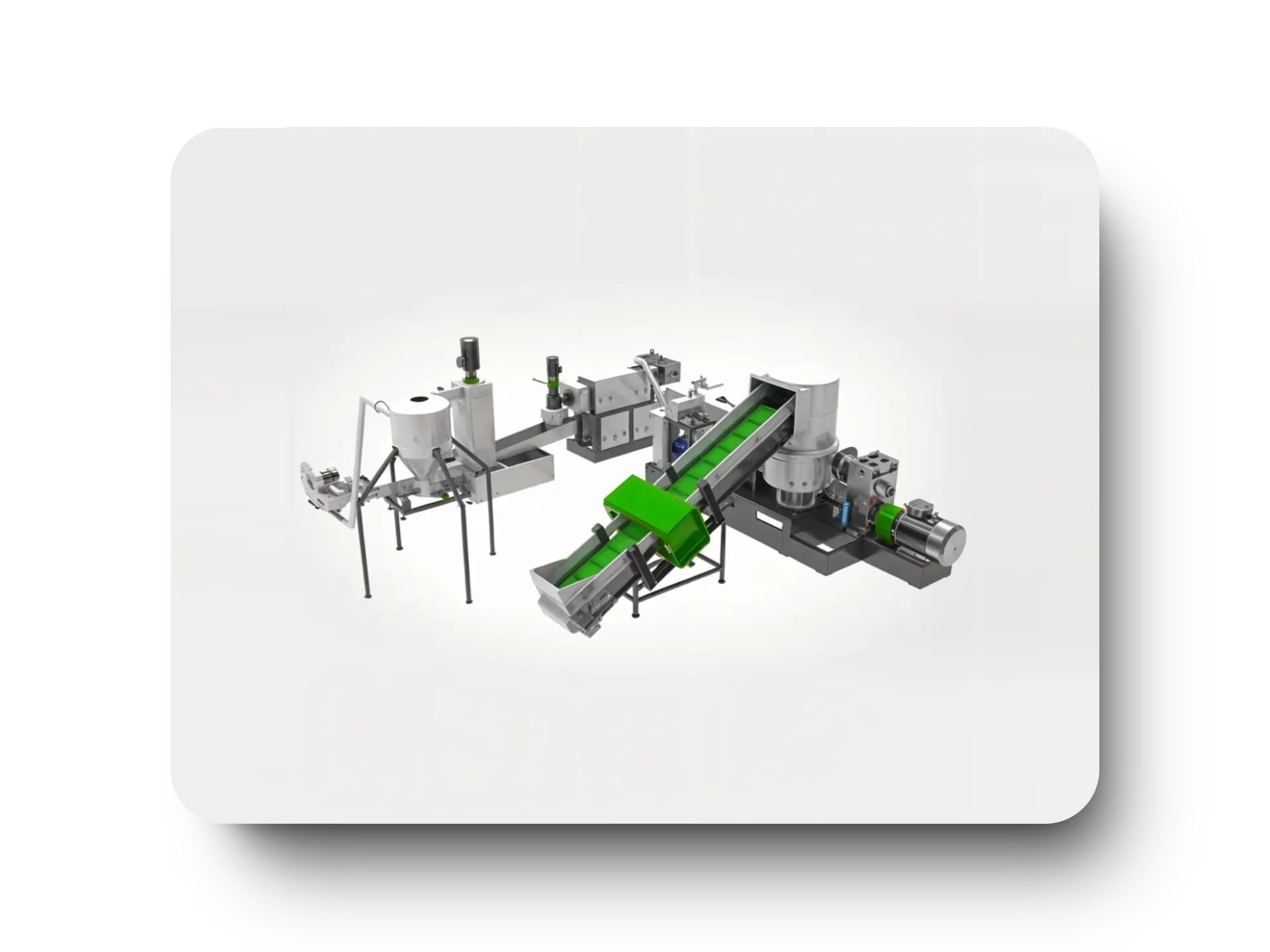

pelletizer/extruder

PET flakes are mostly used directly, especially in the production of polyester fiber. Nevertheless, we have customers who require plastic pelletizing machines, such as our single-screw and twin-screw extruder pelletizers.

Frequently Asked Questions

Find answers to frequently asked questions about our recycling machine

What is a PET bottle recycling machine?

A PET bottle recycling machine is a specialized piece of equipment designed to process used polyethylene terephthalate (PET) bottles and convert them into reusable raw materials. This machine typically performs functions such as shredding, washing, drying, and pelletizing, effectively preparing the PET for reprocessing into new products such as fibers, containers, or automotive parts. The efficient operation of a PET recycling machine not only helps reduce plastic waste, but also supports environmentally friendly practices by promoting the circular economy.

How does a PET bottle recycling machine work?

The operation of a PET bottle recycling machine typically involves several key steps. First, the PET bottles are collected and fed into a shredder where they are broken down into smaller pieces. These pieces are then washed to remove contaminants such as labels, adhesives and dirt. After washing, the clean PET flakes are dried and often pelletized, turning them into small pellets or granules that can be used by manufacturers to produce new products. The entire process helps to minimize environmental impact and conserve resources.

What are the advantages of using a PET bottle recycling machine?

There are numerous benefits to using a PET bottle recycling machine. First and foremost, it significantly contributes to reducing plastic waste in landfills and oceans, thus combating pollution. In addition, recycling PET conserves natural resources and saves energy compared to producing new PET from raw materials. This machine also creates economic opportunities by generating jobs in the recycling industry. By converting waste into functional materials, it supports sustainability initiatives and promotes responsible consumption, which ultimately benefits the environment and society.

Which types of PET bottles can be processed?

Most PET bottle recycling machines can process a wide variety of PET bottles, including those used for beverages, household products and personal care items. However, it is important to ensure that these bottles are thoroughly cleaned to remove any remaining liquids or contaminants. Paper or plastic labels can usually be processed; however, highly adhesive or multi-layered packaging may require additional processing techniques. A good understanding of the machine's specifications will help to optimize the recycling process.

How much does a PET bottle recycling machine cost?

How much does a PET bottle recycling machine cost?

The cost of a PET bottle recycling machine can vary significantly depending on size, capacity, level of automation and additional features. Small, basic models start at a few thousand dollars, while more advanced and larger machines can cost tens or even hundreds of thousands of dollars. Companies should consider their recycling volume and operational needs when selecting a machine. It is recommended to do thorough research and compare options from reputable manufacturers to ensure good value for money.

Where can I buy a PET bottle recycling machine?

Where can I buy a PET bottle recycling machine?

PET bottle recycling machines can Rumtoo Machinery , a specialized manufacturer and supplier with a focus on recycling technology. As an industrial machinery supplier, Rumtoo Machinery has its own recycling equipment division and is known for quality and customer service. Additionally, you can browse online marketplaces or attend trade shows to discover a wide range of options. In addition, contacting local recycling organizations can provide valuable recommendations and insight into the best machines for your specific needs.