Choosing a cost-effective yet effective PET recycling plant is critical for small and medium-sized enterprises (SMEs) seeking a balance between cost-effectiveness and sustainability. This comprehensive guide is designed to help engineers, industrial equipment buyers, and technical personnel understand how to select the right cost-effective PET recycling equipment without compromising on quality and productivity.

Understanding PET recycling plants: What SMEs need to know

Polyethylene terephthalate (PET) recycling plants are designed to process PET plastic waste—primarily bottles and containers—into reusable pellets or flakes. For SMEs, selecting the right recycling plant can significantly impact operational efficiency, cost management, and overall competitiveness.

Typical workflow of a PET recycling plant:

- Sorting and pretreatment

- Chopping or grinding

- Washing and drying

- Melting and extrusion

- Granulation or pelletizing

Understanding these processes helps SMEs make informed decisions based on their production needs.

Factors to consider when choosing a budget-friendly PET recycling facility

When evaluating PET recycling equipment, SMEs should prioritize the following key aspects:

1. Production capacity vs. budget constraints

Balancing production capacity with your available budget is essential. Equipment is generally categorized into:

- Small systems: Under 500 kg/hour, ideal for start-ups or low-volume recycling operations.

- Medium-sized systems: Between 500-2000 kg/hour, suitable for growing SMEs.

- Large-scale plants: Over 2000 kg/hour, recommended for established recycling companies.

Recommendation: SMEs generally benefit from medium-sized plants for balanced cost efficiency and capacity.

2. Energy efficiency and operating costs

Energy-efficient equipment can significantly reduce operating costs. Look for recycling facilities with:

- Frequency converters (FU) for motors

- Energy-efficient heating systems

- Automated processes to reduce energy consumption

Pro tip: A slightly higher initial investment in energy-efficient models leads to significant cost savings over time.

3. Quality and consistency of the output

The quality of recycled PET flakes or pellets directly influences their market value. Choose machines that ensure consistency in particle size, color, and purity.

- Washing and drying efficiency: High-quality plants produce flakes with lower contamination.

- Filtration and extrusion: Effective filtration ensures better quality pellets.

4. Ease of maintenance and availability of spare parts

Downtime due to maintenance significantly impacts productivity. Choose manufacturers with:

- Easily available spare parts

- Excellent technical support and customer service

- Clear maintenance guidelines and plans

Performance comparison of PET recycling equipment

To better illustrate the differences, here is a simplified performance comparison:

Recommendation for SMEs: A mid-range system often offers the best balance between initial investment, operating costs and output quality.

Common pitfalls that SMEs should avoid

1. Overestimation of production needs

Avoid purchasing equipment that exceeds your immediate or short-term production capacity, as this will unnecessarily increase costs.

2. Ignoring long-term costs

Evaluate operating costs, including energy, maintenance, and labor. Higher initial costs can often result in lower total lifetime costs.

3. Selecting equipment based solely on price

The cheapest equipment often has hidden costs due to downtime, inefficiency, and lower output quality.

Case study: Success story of an SME in implementing a cost-effective PET recycling plant

Scenario: A small recycling company in Malaysia implemented a medium-sized PET recycling plant with an initial capacity of 800 kg/hour. Despite the slightly higher initial cost compared to cheaper alternatives, the company recorded:

- 25 % lower operating costs for energy

- Reduced downtime through readily available spare parts

- Improved market competitiveness through high-quality recycled PET flakes

Result: The company achieved an ROI within two years, highlighting the value of a balanced selection of equipment.

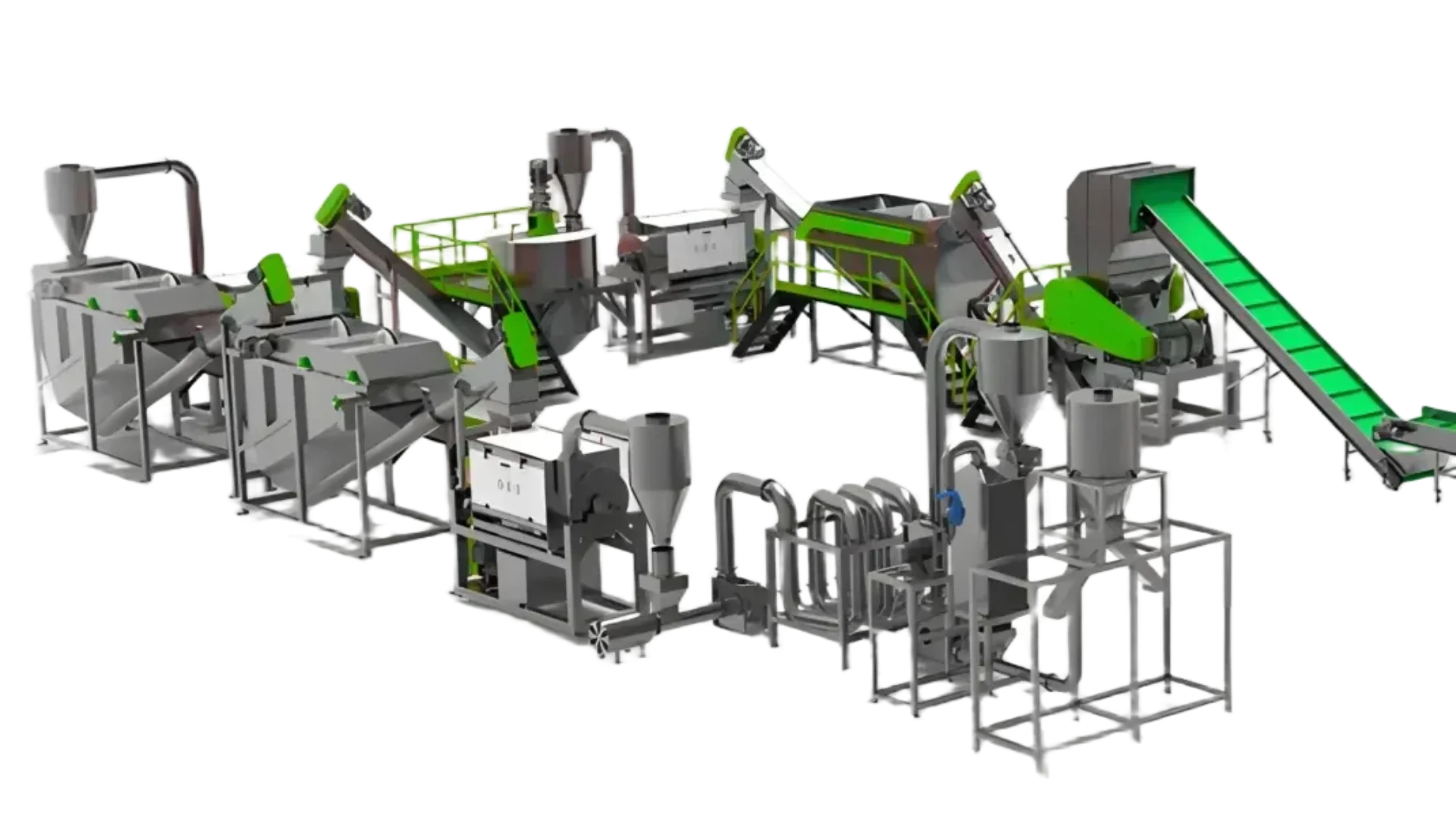

Visualization of the workflow of a PET recycling plant (illustration example)

A simplified visual representation of a typical PET recycling process can improve understanding:

PET waste bottles → Sorting → Shredding/Grinding → Washing → Drying → Extrusion → Pelletizing → Recycled PET pellets

Conclusion: Make an informed decision

Selecting a PET recycling plant is an important investment decision for SMEs. By carefully considering production requirements, long-term operating costs, and equipment reliability, SMEs can realize sustainable and profitable recycling operations.

With the insights provided in this guide, SMEs will be better equipped to navigate the complexities of purchasing affordable, efficient, and reliable PET recycling equipment and ultimately strengthen their competitive advantage in the recycling industry.